Pitch Of An Aircraft - We tried slimline seats out recently in Germany, and were impressed -- although in fairness that's because Lufthansa decided to split the difference with passengers. The airline gets more seats on the plane, and passengers get a bit more legroom.

These angles are only meaningful in a given coordinate system. We typically use a system where all angles zero means you are pointing North and wings and body are parallel to the ground. Based on this starting point you would apply the given angles.

Pitch Of An Aircraft

Straightening, cutting, shaping and balancing a propeller is certainly beyond the equipment capabilities of the average builder. It is better to entrust these technical operations to an Approved Prop Shop. In return, you will ordinarily receive a good serviceable prop, a yellow tag, and peace of mind.

The Singularities

Finally, the bank angle $\phi$ (phi, sometimes called the roll angle) is slightly more complicated. The range of possible bank angle values is a full circle, going from 0, to 90 degrees right, to 180 degrees, to 90 degrees left, and back to 0. (There's no difference between "180 degrees left" and "180 degrees right.")

TheRealBabushka: lighten up dude. Not only is AusBT not just a 'news' site as John said, with lots of articles for general reference and information, but the guys were at Sydney Airport yesterday morning, Sunday, to cover the new QF A330 when most of us were in bed or having breakfast. I don't think you can then take a shot at them as if they're lazy!

WEIGHT AND BALANCE IS A FACTOR Determine from your weight and balance calculations whether you need a heavier prop (metal) or a light (wood) propeller. The wood prop will be lighter by about 10 pounds for the smaller engines.

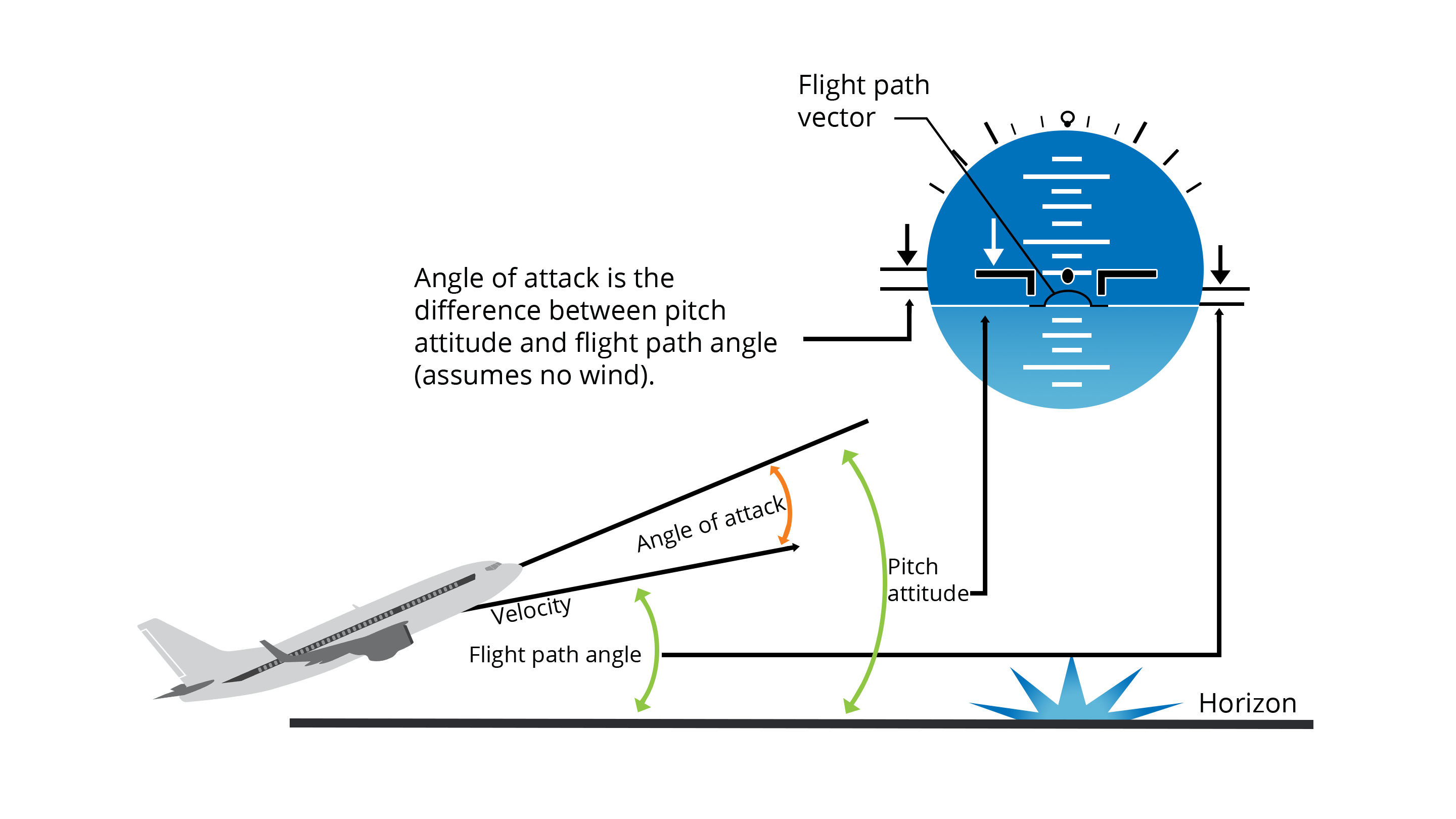

It depends somewhat on whether you are speaking from a pilot's point of view or from an engineer's point of view. Your reference to yaw, pitch, and roll ANGLES is indicates you are looking at the situation from an engineering point of view. A pilot would tend to think more in terms of yaw, pitch, and roll as expressing RATES of rotation, or in some cases as expressing angular (rotational) changes from the aircraft's PREVIOUS POSITION rather than from a prescribed starting reference position. If the desire is to express the aircraft's 3-dimensional position in space relative to the plane of the ground and relative to north, a pilot would tend to speak of heading, pitch ATTITUDE, and roll ATTITUDE (or bank angle). But read on for more.

Earn Bonus Points - Stgeorge Amplify Signature

EAA members in scattered areas have already been reacting to the problem. By the time this article appears you may have read quite a bit on the subject of propeller failures . . . about propellers being cut down beyond limits authorized by the propeller manufacturer and about the game of Russian Roulette being played with unknown propeller vibrational stresses. Take a look at Figure 1 again and note that most of the propeller diameters listed are greater than those typically found on a large number of homebuilts.

Who Has A Prop You Can Try? Do you or a fellow builder own a spare propeller that you could try? If so, first find out whether that propeller hub will fit your engine. Lycoming engine flanges are not the same as those on Continental engines. Then, too, propeller bolt hole sizes vary. Naturally, Volkswagen engines have still another bolt pattern and the same can be said of other engine conversions. Anyhow, if the prop hub fits your engine, fine. Why not give it a try. I assume that you will have plenty of ground clearance. And how about weight and balance? Can you accept the weight of a metal prop - assuming it is metal?

YOUR AIRPLANE IS just about finished and you do not yet have a propeller for it. Joe down the street has a good metal prop but the tips are curled from a taxiing accident. Joe doesn't know what aircraft it came from but he realizes he won't need one himself for a couple of years, so he will let you have it pretty cheap. The offer is tempting for you have just found out what the prices are for new metal props. The money you have set aside may not be enough for a new propeller. Even if it were, can you afford to pay a big price for a new propeller, which may not be exactly right for your bird? What to do?

The angles α, β and γ are uniquely determined except for the singular case that the xy and the XY planes are identical, i.e. when the z axis and the Z axis have the same or opposite directions. Indeed, if the z axis and the Z axis are the same, β = 0 and only (α + γ) is uniquely defined (not the individual values), and, similarly, if the z axis and the Z axis are opposite, β = π and only (α − γ) is uniquely defined (not the individual values). These ambiguities are known as gimbal lock in applications.

You can find the heading by pointing your finger in the direction the nose is pointing, then moving your finger straight up or down until it meets the horizon. The heading is the direction your finger is pointing.

Lycoming advises that, when using a fixed pitch propeller, the static rpm should be 2300 plus or minus 50 rpm when the engine is rated at 2700 rpm. This will vary slightly depending on the type of propeller. If the static rpm is too high, there is the chance of overspeeding at full throttle level flight. (With a constant speed propeller, static rpm will be the rated rpm of the engine. This is controlled by the low pitch settings of the propeller.)

What are these angles referenced to? For example, R, P, Y all start from 0, plane is flying horizontal, then it inclines its nose by 90 degrees, moving vertical like a rocket. Now pitch is 90 degrees, but what now determines the roll? While moving horizontal, roll may be the angle between the normal vector of the earth's surface and the airplane's up vector. But when pitch = 90 degrees, what is roll?

But again, if we are using the system of Euler angles as described above for engineering purposes, then we might reasonably assume that "yaw", "pitch", and "roll" may be used to denote the corresponding Euler angles with no further elaboration. This wouldn't be normal pilot-speak.

Low Altitude Level Flight Here is an important check for your propeller. Let's assume your engine is a Lycoming 0-320 (150 hp). Your prop should allow it to develop its maximum rated 150 hp at 2700 rpm using full throttle in level flight at sea level - assuming a standard day (temperature 59 degrees F, and sea level pressure of 29.92 Hg). Obviously, this sort of check is impossible for most of us unless we fly to some place called "Bad Water" in Death Valley where it is approximately 254 feet below sea level.

At this point the representative aircraft shown in Figure I may or may not be considered as particularly helpful. After all, how many homebuilt are as large as the Piper Cub or are like the Ercoupe? I guess this is exactly where the problem really shows. The size of the homebuilts, their weight, and their (generally) lower drag characteristics, certainly, are different from the larger store boughts.

If this information becomes available later, we will pass it along as well. The propeller pitch range shown, in some cases, is the absolute maximum authorized by the propeller manufacturer. In other cases it merely reflects the composite limits for the representative aircraft listed and the authorized limits for that prop Model may really be just a bit greater. However, stick to the numbers shown, or check with the manufacturer, or Propeller Shop, before you do anything drastic.

Pitch, on the other hand, is the distance in inches that a propeller section will advance in one revolution. Both blade angle and pitch are measured at the airfoil section located at 75% of the blade radius, but apparently not always in the same manner. That invites the possibility that the blade angle you measure may not translate into the advertised pitch. It is, therefore, useless to try to compare propellers from different sources relying on pitch only.

Take-Off And Climb Don't expect to get the rated rpm for take-off with a fixed pitch prop. If you do, by the time you reach level flight the engine will be winding up like a turbine and running way over its redline rpm. It is most unlikely, therefore, that with a properly pitched fixed pitch propeller you will be utilizing anywhere near the rated horsepower of the engine for takeoff.

Static RPM Is Important A static rpm check is the best assurance you can have that your engine can handle the installed propeller. Perform your static rpm check by starting the engine and accelerating it smoothly up to full throttle (no wind condition and wheels chocked, of course). The engine should be able to reach approximately 80% to 85% of its rated (redline) rpm. A minimum static rpm has been established for each aircraft engine.

The pitch is always defined. However, if the nose is pointing straight up or down, then the aircraft no longer has a heading or bank angle as described above. There's no heading because the nose isn't pointing horizontally at all; and there's no bank angle because it's not possible to roll the aircraft such that the top side is facing up.

Nevertheless, I don't believe that there is a flagrant or deliberate intent by the homebuilder to disregard the engineering guidance available regarding the propellers/engine/airplane match. How come, then the situation that we have? An informal check of my own showed, that of the many projects I checked, NOT ONE was equipped with a new metal propeller . . .

Pitch is still important at the pointy end of the plane, though: the more space there is in front of you, the easier it is for window passengers to nip out over a sleeping aisle passenger.

On many aircraft, the horizontal stabilizer and elevator create a symmetric airfoil like the one shown on the left of the shape effects slide. This produces no lift when the elevator is aligned with the stabilizer and allows the combination to produce either positive or negative lift, depending on the deflection of the elevator. On many fighter planes, in order to meet their high maneuvering requirements, the stabilizer and elevator are combined into one large moving surface called a stabilator. The change in force is created by changing the inclination of the entire surface, not by changing its effective shape.

STATIC RPM AS A GUIDE Once you have a propeller, the static rpm that your engine can turn up with that a particular prop is a good indicator of whether or not it can get you off the ground safely. By static rpm, we mean the rpm the engine is capable of reaching at full throttle while the aircraft is stationary.

Euler angles are relative to earth axes. Pitch, roll and yaw are relative to aircraft axes. Pitch means: nose up/down. Roll means: wingtip up/down. Yaw means: nose left/right. All from the pilots viewpoint. It is that simple.

Static rpm is established for all certificated engines. If your engine is not one of those shown in Figure 2, check with any local A&P mechanic or repair shop. What does this static rpm mean to you? Well, if you full throttle your engine and it does not rev up to the recommended static rpm . . . it is quite possible that the prop is too big in diameter or that it has too much pitch, maybe both. It means that perhaps you won't get enough thrust from that prop for a safe take-off. What if your static rpm is much higher than that recommended? Well, you may get off' O.K. but there is the possibility of exceeding the red-line limits for your engine, even during the takeoff sequence.

Well, how about buying a new certificated wood propeller? A FAA approved wood prop (suitable for most certificated light aircraft) does have a somewhat more sane price tag - it costs only half as much as a metal propeller. It also has less than half the weight of a metal prop. This could be an important weight and balance consideration.

The closest you might come to those conditions would be a full throttle, level flight below 3000 feet early some morning when the air is nice and smooth. The engine rpm should turn up to approximately 5% over the rated 2700 (redline) rpm. This would result in a maximum level flight rpm of approximately 2850. Two or three minutes at this excess rpm certainly should not hurt the engine. Throttle back to 75% power and you should be getting a nice cruise speed at approximately 93% of redline rpm (2500 rpm). A prop whose pitch and diameter permit this rpm to be reached under the conditions described will provide plenty of rpm for take-off and climb.

Have you noticed lately that most newly completed homebuilts, except for an occasional Pietenpol or Volksplane, of course, "cruise" over 200 mph? There are computer whizzes and armchair theorists who periodically challenge such claims and cite certain mathematical and aerodynamical "realities", but I for one do not intend to get into that hassle. I will, instead, offer a few suggestions for selecting your first propeller.

The key thing missing in your interpretation is that the order is important. Applying the same roll, pitch and yaw angles in a different order will result in a different orientation (mathematically this is because rotation matrices do not commute).

(In fact, interesting aside: I first decided to write this article because I was fed up of saying "that's the space between your seatback and the back of the seat in front of you, not counting the tray table -- in other words, what you can call your personal space on a plane".)

One more word on propeller diameter. Have you ever heard of this one? "Keep your prop as long as possible as long as possible!" I'll give you one good argument for longer prop diameters. Next time you get near a nice homebuilt with a beautifully cowled engine . . . just check and see how much of the propeller area is blanketed out by the engine cowl when the prop is in the horizontal position.

The McCauley Industrial Corporation has offered the advice that all of the EAA people should be encouraged to use a propeller within the diameter range that is approved vibration-wise on the engine. Too many of them, they said, are using short diameters on 4-cylinder engines which may get them into trouble.

parts of an airplane, elevator pitch aircraft, aircraft seat pitch, yaw pitch roll, aircraft pitch control, top 10 airplane manufacturers, aircraft yaw, aircraft roll pitch yaw

0 Comments